Paintable Silicone Supreme Window & Door Sealant

- 100% weatherproof

- 10-year mold-free product protection†

- Permanently flexible

- 60-minute paint-ready†

- 30-minute rain-ready†

- Shrink & crack-proof

- Ideal for exterior, weatherproofing & painting projects

- Low odor

- Lifetime guarantee†

†See Product Disclaimers page for important details

Paintable Silicone Supreme Window & Door sealant is a premium, 100% weatherproof sealant with a hybrid formula that combines the outstanding waterproof performance you would expect from a silicone sealant with the ease of use and paintability of an acrylic latex. Ideal for exterior weatherproofing projects, this formula is designed to provide a reliable seal in areas that may be exposed to moisture and require painting. This sealant is permanently flexible with long-lasting durability and offers 10-year mold-free product protection that resists stain-causing mold and mildew growth. Backed by a lifetime guarantee.

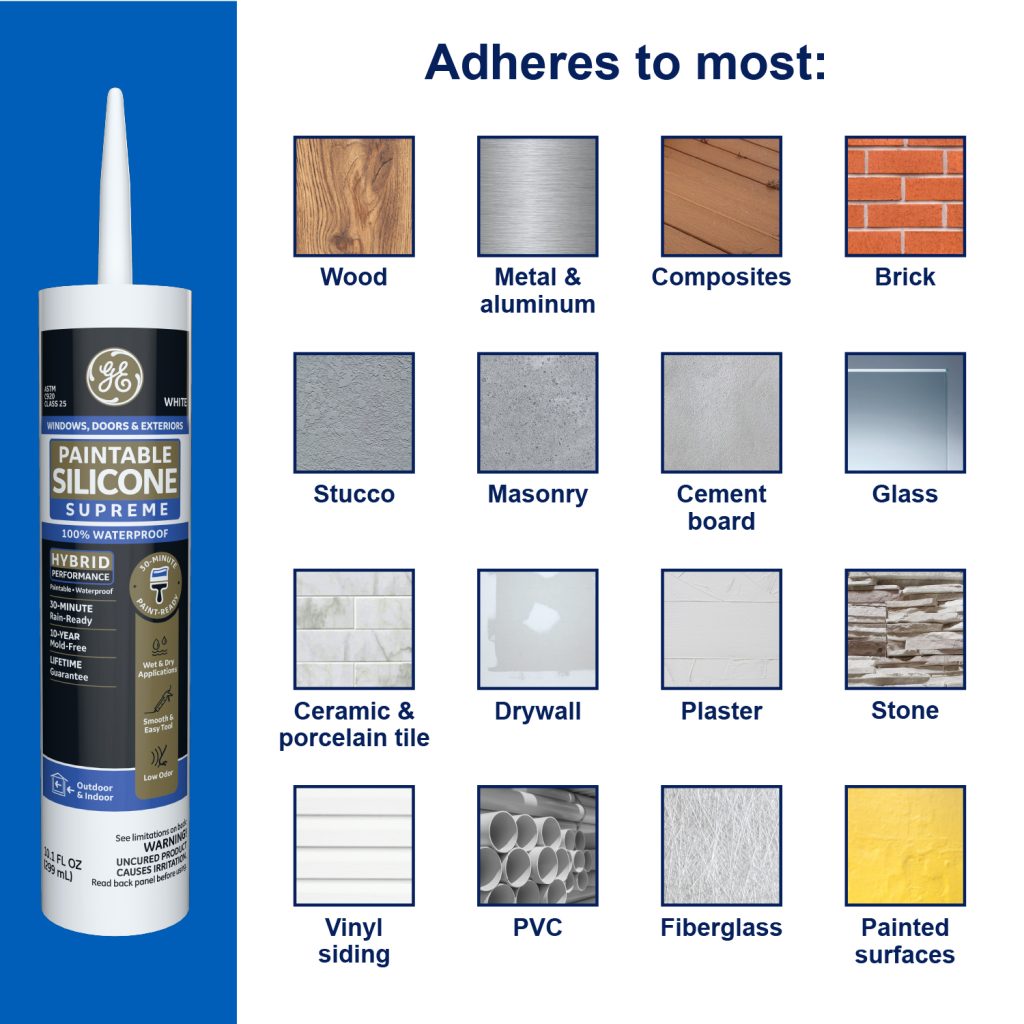

Adheres to: most metals & woods, aluminum, composites, brick, stone, stucco, masonry, cement board, glass, ceramic & porcelain tile, drywall, plaster, vinyl siding, PVC, fiberglass & painted surfaces

For additional information, see product label.

- Remove dirt, grease, moisture, soap residue & old sealant from area to be sealed. Use backer rod for gaps larger than 1/2″ x 1/2″.

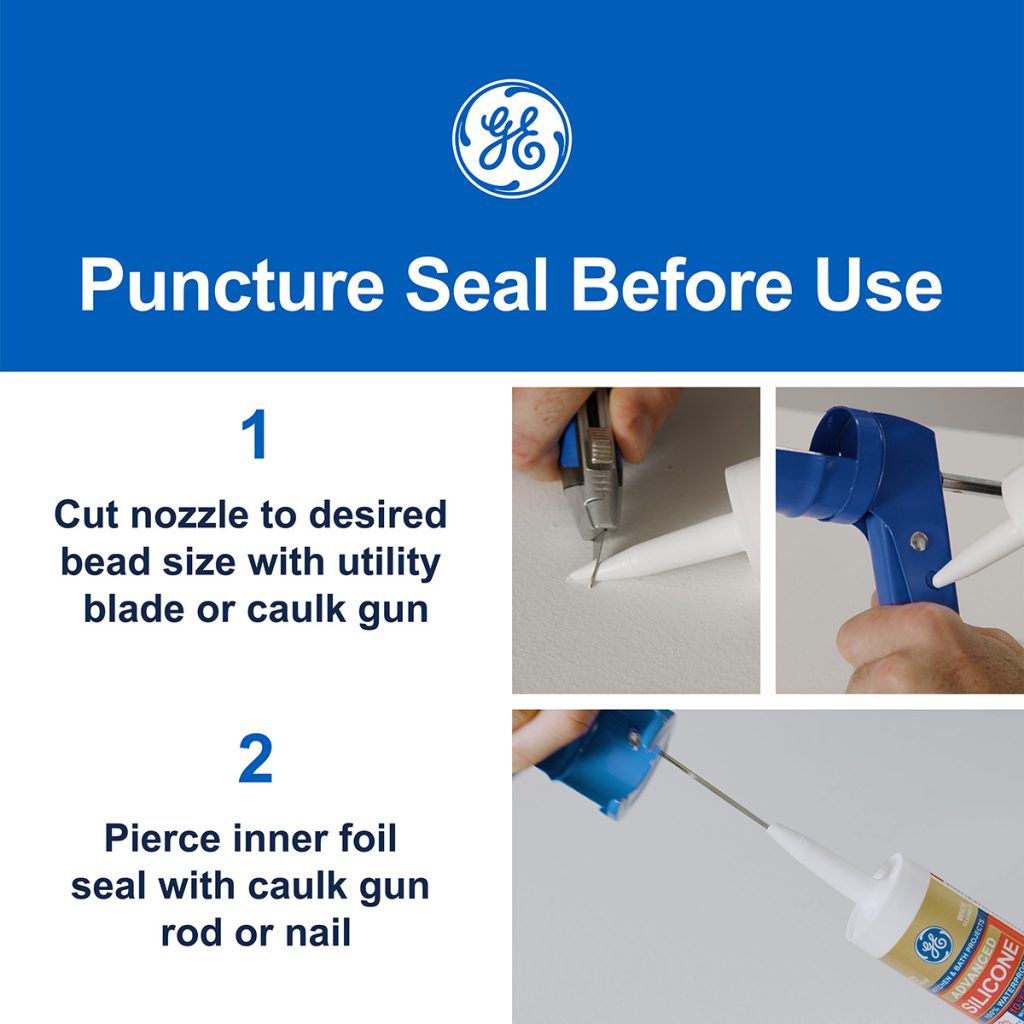

- Cut nozzle to obtain desired bead size.

- PIERCE INNER FOIL SEAL.

- Using caulk gun, apply sealant into gap. Smooth with a gloved finger or “tool” the caulk into gap.

- Wipe hands & tools thoroughly before washing.

- Allow 30 minutes before exposing sealant to water.

Meets ASTM C-920, Type-S, NS, Class 25, use NT, G, A & O test requirements

Fed Spec TT-S-00230C, TT-S-001543A

For products produced by Henkel Corporation, please use the UPC Code. You can click on the corresponding UPC code below to access the SDS..

For products produced by Henkel Corporation, please use the UPC Code. You can click on the corresponding UPC code below to access the SDS..

| Color | UPC Code |

|---|---|

| White |

US - 61083642488

ESP - 61083642488 |

Paintable Silicone Supreme Window & Door Sealant Paintable Silicone Supreme Window & Door Sealant |  All Purpose Silicone 1® Sealant All Purpose Silicone 1® Sealant |  Supreme Silicone Window & Door Sealant Supreme Silicone Window & Door Sealant | |

|---|---|---|---|

| Water-ready Time | 30-minute | 24 Hours | 30-minute |

| Mold-Free Product Protections | 10-year | 7-year | Lifetime |

| Joint Movement | 50% | 25% | 50% |

| Paintable | |||

| Low Odor | |||

| Will Not Blemish Most High-End Metals |

Swipe to scroll the table horizontally